A manual bottle filling machine is a device designed to fill bottles with liquids, offering precision and efficiency in various industries․ It is ideal for small-scale production, providing cost-effective solutions for businesses and homemade products, ensuring minimal waste and easy operation․

1․1 What is a Manual Bottle Filling Machine?

A manual bottle filling machine is a device designed to fill bottles with liquids, operated by hand or through simple mechanical processes․ It is typically used for small-scale production, offering precision and efficiency in filling containers with consistent volume․ These machines are cost-effective, easy to use, and require minimal setup, making them ideal for businesses and individuals producing homemade products like oils, cosmetics, and beverages․ They ensure accurate filling with minimal waste, providing a practical solution for various industries․

1․2 Purpose and Functionality

A manual bottle filling machine is designed to precisely fill bottles with liquids, ensuring consistency and minimizing waste․ Its primary function is to simplify the bottling process, offering control over fill levels and flow rates․ Suitable for various industries, it helps small businesses and startups efficiently package products like beverages, oils, and cosmetics․ With minimal controls, it operates through basic mechanisms, making it user-friendly and ideal for low to medium production volumes․

1․3 Brief History and Evolution

Manual bottle filling machines trace their origins to the late 19th century, emerging as simple, hand-operated devices for bottling liquids․ Over time, they evolved to incorporate basic mechanical components, improving accuracy and efficiency․ The mid-20th century saw standardized designs, while modern versions now feature enhanced materials and ergonomic designs․ This evolution reflects the growing demand for affordable, reliable bottling solutions across various industries, making manual machines a cornerstone of small-scale production and artisanal manufacturing․

Types of Manual Bottle Filling Machines

Manual bottle filling machines are categorized into piston-based, gravity-operated, and peristaltic pump systems, each offering distinct advantages for various liquids and bottling needs, ensuring precision and efficiency․

2․1 Piston-Based Manual Filling Machines

Piston-based manual filling machines use a piston to measure and dispense precise volumes of liquid into bottles․ These machines are known for their accuracy and are often used for filling small to medium quantities․ The piston mechanism ensures consistent filling levels, making them ideal for viscous liquids like creams or oils․ They are easy to clean and maintain, with fewer moving parts compared to other types․ Regular lubrication of the piston is essential for smooth operation and longevity․

2․2 Gravity-Operated Manual Filling Machines

Gravity-operated manual filling machines rely on gravity to dispense liquids into bottles․ These machines are simple, with no moving parts, making them highly durable and easy to maintain․ They are often used for filling low-viscosity liquids like water or cleaning solutions․ The machine is filled from the top, and liquid flows into bottles through an open valve․ This design ensures minimal effort and is ideal for small-scale operations․ Cleaning is straightforward, and they are cost-effective for businesses with basic filling needs․

2․3 Peristaltic Pump-Based Manual Filling Machines

Peristaltic pump-based manual filling machines use a flexible hose and rollers to dispense liquids․ They are ideal for handling sensitive or viscous fluids, as the pump gently squeezes the hose without direct contact․ These machines are easy to clean and maintain, with fewer parts compared to other types․ They offer precise control over filling volumes and are commonly used in laboratories, food, and cosmetic industries․ Their compact design and low maintenance make them a popular choice for small to medium-scale operations․

Components and Parts of a Manual Bottle Filling Machine

A manual bottle filling machine includes essential components like a filling nozzle, control panel, bottle rest, and pump․ These parts ensure precise and efficient bottle filling operations․

3․1 Essential Components

A manual bottle filling machine consists of key components such as a sturdy frame, filling tank, pump system, and filling valve․ These parts work together to ensure accurate and consistent filling․ The frame provides stability, while the tank holds the liquid․ The pump transfers the liquid, and the valve controls the flow․ Additional features like a foot pedal or hand lever may be included for easier operation, making the machine user-friendly and efficient for small-scale bottling needs․

3․2 Key Parts: Filling Nozzle, Control Panel, and Bottle Rest

The filling nozzle ensures precise pouring, reducing spills and waste․ It is typically adjustable to fit various bottle sizes․ The control panel houses buttons or levers to regulate the flow rate and pressure, offering easy operation․ The bottle rest provides a stable base for bottles, ensuring accurate alignment with the nozzle․ Together, these components enhance efficiency, accuracy, and user convenience, making manual bottle filling machines ideal for small to medium-scale operations․

Operation and Functionality

Manual bottle filling machines operate via simple mechanisms, requiring users to start and stop the filling process․ They ensure precise control over liquid volume, offering efficiency and reliability․

4․1 Step-by-Step Operation Guide

Operating a manual bottle filling machine involves a straightforward process․ First, prepare the machine by ensuring it is clean and placed on a stable surface․ Next, adjust the filling nozzle to match the bottle size and desired liquid level․ Prime the machine if necessary, then place the bottle under the nozzle․ Activate the filling mechanism, such as a lever or pump, to start the flow of liquid․ Once the bottle is filled, turn off the machine and remove the bottle․ Regularly clean and maintain the machine for optimal performance․

4․2 Manual vs․ Semi-Automatic Modes

Manual mode requires physical operation, such as pressing a lever or turning a handle to fill bottles, offering full control over the filling process․ Semi-automatic mode uses basic automation, like preset fill levels or foot pedals, to streamline operations while still requiring some manual intervention․ Manual mode is ideal for small batches and precise control, while semi-automatic mode enhances efficiency and reduces fatigue, making it suitable for slightly larger production needs․

4․3 Safety Features and Precautions

Manual bottle filling machines include safety features like protective guards, secure locking mechanisms, and emergency stop buttons to prevent accidents․ Operators should wear protective gear, ensure proper setup, and follow maintenance schedules․ Proper training and supervision are crucial to safe operation, minimizing injury risks and machine damage․ Adhering to these guidelines ensures efficient and safe functionality․

Applications and Uses

Manual bottle filling machines are widely used in food, beverage, cosmetic, and pharmaceutical industries, suitable for filling water, oil, and various liquids with precision and efficiency․

5․1 Industries That Use Manual Bottle Filling Machines

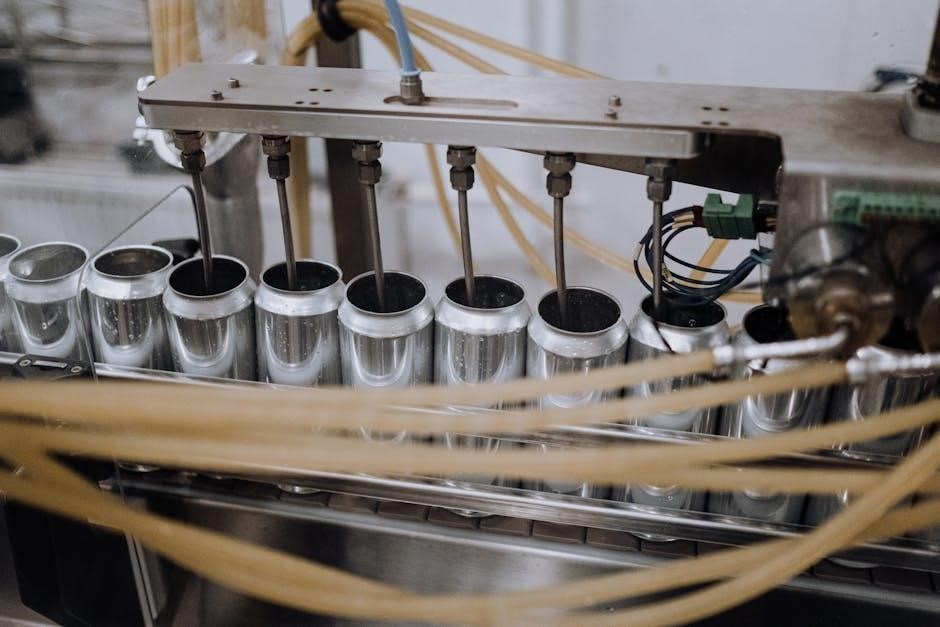

Manual bottle filling machines are widely adopted in the food and beverage industry for packaging water, juices, and sauces․ They are also used in cosmetics for filling lotions, creams, and serums․ Pharmaceutical companies utilize them for small-scale production of ointments and medications․ Additionally, these machines are popular in craft breweries and wineries for bottling samples or specialty products․ Their affordability and ease of use make them ideal for small to medium-scale operations across various sectors․

5․2 Common Products Filled: Water, Oil, Cosmetics, and More

Manual bottle filling machines are versatile, accommodating various products like water, edible oils, and cosmetics․ They are ideal for filling small batches of creams, lotions, and serums․ Additionally, these machines handle food items such as sauces, condiments, and beverages․ They are also used for pharmaceutical products like ointments and medications․ Their adaptability to different viscosities and volumes makes them suitable for a wide range of liquids, ensuring precise and efficient filling in small-scale operations․

Advantages and Benefits

Manual bottle filling machines offer cost-effectiveness, ease of use, and portability, making them ideal for small-scale operations․ They require minimal maintenance, reducing downtime and operational costs․

6․1 Cost-Effectiveness

Manual bottle filling machines are highly cost-effective, offering a low initial investment and minimal operating costs․ They are ideal for small businesses or startups with limited budgets, as they eliminate the need for expensive automation․ Their simple design reduces maintenance expenses and energy consumption․ Additionally, manual machines are often more affordable than automatic ones, making them a practical choice for businesses looking to minimize overhead while still achieving efficient bottling solutions․

6․2 Ease of Use and Portability

Manual bottle filling machines are designed for straightforward operation, requiring minimal training to use effectively․ Their lightweight and compact design makes them highly portable, allowing easy relocation within a workspace․ This portability is especially beneficial for small-scale operations, home-based businesses, or laboratories․ The simplicity of these machines ensures that users can quickly adapt to their functionality, making them practical for environments where ease of use and mobility are essential for efficient bottle filling processes․

6․3 Minimal Maintenance and Downtime

Manual bottle filling machines require minimal maintenance due to their simple, durable design․ With fewer moving parts compared to automatic machines, they experience less wear and tear, reducing downtime․ Cleaning is straightforward, and basic lubrication of components ensures smooth operation․ This makes them ideal for small-scale operations where frequent interruptions are costly․ Their reliability and low maintenance needs contribute to consistent productivity and efficiency in various bottling environments․

Limitations and Challenges

Manual bottle filling machines face limitations like reduced production capacity, potential for human error, and compatibility issues with varying bottle sizes, impacting efficiency and scalability․

7․1 Limited Production Capacity

Manual bottle filling machines are best suited for small-scale operations due to their limited production capacity․ They rely on manual operation, which restricts filling speed and volume․ While they excel in flexibility and cost-effectiveness for low to medium production needs, they are not ideal for high-volume applications․ This makes them less practical for large industries requiring rapid bottling solutions, emphasizing their suitability for startups, small businesses, or specialized product lines․

7․2 Potential for Human Error

Manual bottle filling machines are prone to human error due to their reliance on operator intervention․ Errors such as overfilling, underfilling, or improper bottle alignment can occur, leading to inconsistencies․ Additionally, manual operation may result in spills or inaccuracies, especially with viscous liquids․ These machines require precise handling and attention to detail, making operator training and clear guidelines essential to minimize mistakes and ensure consistent filling results․

7․3 Compatibility with Different Bottle Sizes

Manual bottle filling machines may face challenges with compatibility across various bottle sizes․ Many machines are designed for specific bottle dimensions, requiring adjustments or additional parts for different sizes․ This can lead to inefficiencies, especially for businesses handling multiple bottle types․ Ensuring the machine’s adjustability or having interchangeable components is crucial for seamless operation․ Compatibility issues can affect accuracy and efficiency, making it important to select a machine that suits your specific needs and bottle variety․

Maintenance and Troubleshooting

Regular maintenance is crucial for optimal performance․ Cleaning and lubricating parts ensure longevity․ Troubleshooting common issues like clogs or misalignments helps maintain efficiency and reduces downtime effectively․

8․1 Regular Cleaning and Lubrication

Regular cleaning and lubrication are essential for maintaining the efficiency of manual bottle filling machines․ Clean the filling nozzle and other components daily to prevent residue buildup and contamination․ Use mild detergents and dry thoroughly to avoid rust․ Lubricate moving parts like pistons and gears regularly to reduce friction and wear․ This ensures smooth operation and extends the machine’s lifespan․ Always use food-grade lubricants to maintain safety standards․

8․2 Common Issues and Solutions

Common issues with manual bottle filling machines include inaccurate filling levels, leakage, and mechanical jams․ To address these, check and calibrate the filling nozzle regularly․ Tighten loose connections to prevent leaks․ For jams, clean debris from the piston or gears․ Lubricate moving parts if they stick․ Ensure bottles are properly aligned to avoid uneven filling․ Refer to the user manual for specific troubleshooting steps to resolve issues quickly and maintain optimal performance․

Choosing the Right Manual Bottle Filling Machine

Assess your needs, product type, and bottle size to select the ideal machine․ Consider speed, budget, and brand reputation for a reliable and efficient solution․

9․1 Factors to Consider: Product Type, Bottle Size, and Speed

When selecting a manual bottle filling machine, consider the viscosity and type of product, as some machines are better suited for liquids like water or oil․ Bottle size and shape are crucial, as machines may need adjustments for different capacities․ Speed is another factor; manual machines are ideal for small batches, but higher-speed models can handle slightly larger volumes․ Assessing these elements ensures the machine aligns with your production needs and operational efficiency․

9․2 Budget and Brand Reputation

Budget is a critical factor when selecting a manual bottle filling machine․ While cheaper options may seem appealing, prioritize durability and functionality․ Reputable brands often offer higher-quality machines with better customer support and warranties․ Balancing cost and quality ensures long-term efficiency and reliability․ Investing in a trusted brand can prevent future issues and extend the machine’s lifespan, making it a worthwhile expenditure for consistent performance and satisfaction․

Design and Customization

Manual bottle filling machines offer customizable designs to suit various needs․ Stainless steel frames and adjustable nozzles are common features, ensuring durability and adaptability for different bottle sizes and products․

10․1 Customizable Features

Manual bottle filling machines can be tailored to meet specific requirements․ Key customizable features include adjustable fill levels, nozzle sizes, and product compatibility․ Users can modify the machine’s frame, materials, and controls to suit their workflow․ Some models allow for interchangeable parts, enabling adaptation to different bottle sizes and shapes․ Customizable settings ensure precise filling for liquids of varying viscosities, enhancing efficiency and accuracy in diverse applications․

10․2 DIY Modifications and Upgrades

Manual bottle filling machines can be modified and upgraded to enhance functionality․ Users can add accessories like foot pedals for hands-free operation or install digital displays for precise measurements․ Upgrading parts such as nozzles or fill level controls can improve efficiency and accuracy․ DIY modifications may also include custom attachments for specific bottle sizes or shapes․ These upgrades extend the machine’s versatility, allowing it to adapt to evolving production needs without significant costs․

Market and Industry Trends

The demand for manual bottle filling machines is rising, especially in small-scale industries, due to their affordability and simplicity․ Market trends show increased adoption in craft beverages and homemade products, driven by customization needs․ Additionally, eco-conscious consumers favor manual machines for their minimal energy consumption and sustainable operation․ This growth highlights a shift toward cost-effective, user-friendly solutions in packaging processes․

11․1 Growth of Manual Filling Machines in Small Businesses

Small businesses are increasingly adopting manual bottle filling machines due to their affordability and ease of use․ These machines are ideal for low-to-medium production volumes, making them perfect for startups and artisans․ The rise of DIY and small-batch production, particularly in craft beverages, cosmetics, and specialty foods, has fueled demand․ Manual fillers offer flexibility, allowing businesses to scale gradually without heavy investment, while maintaining precision and control over the filling process․ This trend reflects a shift toward cost-effective, adaptable solutions for growing enterprises․

11․2 Technological Advancements

Technological advancements have significantly enhanced the performance of manual bottle filling machines․ Modern designs now incorporate durable materials like stainless steel for longevity and hygiene․ Improved mechanisms, such as precise piston controls and anti-drip systems, ensure accuracy and efficiency․ Digital integration, such as touchscreens for preset volumes, has also emerged, blending manual operation with smart technology․ These innovations make manual fillers more versatile, user-friendly, and adaptable to diverse industrial needs, boosting their appeal in competitive markets․

User Safety and Precautions

Ensure proper training and wear protective gear like gloves and goggles․ Handle machines with care to avoid spills and injuries․ Keep the workspace clean and stable․

12․1 Handling Precautions

Always wear protective gear like gloves and goggles when operating a manual bottle filling machine․ Avoid overfilling bottles to prevent spills and ensure a stable workspace․ Regularly inspect the machine for leaks or damage․ Keep hands away from moving parts and avoid using excessive force․ Ensure the machine is placed on a level surface to maintain balance․ Proper handling reduces the risk of accidents and ensures smooth operation․ Follow the manufacturer’s guidelines for safe usage and maintenance․

12․2 Emergency Shutdown Procedures

In case of an emergency, immediately switch off the power supply to the manual bottle filling machine․ Release any pressure in the system by slowly opening the relief valve․ Avoid sudden movements that could cause spills or damage․ If a malfunction occurs, stop operation and unplug the machine․ Do not attempt repairs without proper training․ Always refer to the manufacturer’s emergency shutdown guidelines for specific instructions․ Prioritize safety to prevent accidents and ensure proper machine functionality․

Environmental Impact

Manual bottle filling machines promote sustainability by reducing energy consumption and minimizing waste․ They often use recyclable materials and produce fewer emissions, supporting eco-friendly practices․

13․1 Eco-Friendly Aspects

Manual bottle filling machines are inherently eco-friendly due to their low energy consumption and minimal environmental impact․ They typically operate without electricity, reducing carbon emissions and reliance on non-renewable resources․ These machines often use recyclable materials, contributing to sustainability efforts․ Their compact design and simple mechanics also result in less waste during production and operation․ By choosing manual filling machines, businesses can significantly reduce their ecological footprint while maintaining efficient and reliable performance․ This makes them an ideal choice for environmentally conscious industries and consumers alike․

13․2 Waste Reduction and Efficiency

Manual bottle filling machines contribute significantly to waste reduction by minimizing spillage and overfilling․ Their precise filling mechanisms ensure accurate control, reducing excess product usage․ Additionally, these machines often feature easy-to-clean designs, which prevent residue buildup and contamination․ This not only conserves resources but also reduces waste generation․ Their compact and portable nature further enhances efficiency, allowing for optimal use in various settings without unnecessary energy consumption or material waste․

User Reviews and Feedback

Users praise manual bottle filling machines for their simplicity and cost-effectiveness․ Many highlight ease of use and portability, while some note occasional challenges with bottle size compatibility․

14․1 Positive Experiences

Many users commend manual bottle filling machines for their simplicity and efficiency․ They are often praised for being cost-effective and easy to operate, making them ideal for small-scale operations․ Portability is another key advantage, allowing users to fill bottles in various settings effortlessly․ The machines’ durability and minimal maintenance requirements also receive positive feedback․ Overall, these machines are highly regarded for their reliability and ability to streamline bottling processes without requiring advanced technical skills or significant financial investment․

14․2 Common Complaints and Improvements

Some users report challenges with manual bottle filling machines, such as limited speed for bulk orders and occasional inaccuracies in filling levels․ Others note that repetitive use can be physically demanding․ To address these issues, improvements like adjustable speed settings, enhanced filling accuracy, and ergonomic designs are often suggested․ Additionally, better compatibility with viscous liquids and easier cleaning mechanisms would greatly enhance user satisfaction and overall machine performance․

Comparison with Automatic Bottle Filling Machines

Automatic machines offer higher speed and efficiency, while manual counterparts provide simplicity and cost-effectiveness for small-scale operations․ Ideal for businesses needing scalability or specific production requirements without automation․

15․1 Key Differences

Manual bottle filling machines rely on human operation, offering simplicity and portability, while automatic machines are faster and handle large volumes with minimal manual intervention․ Automatic systems are ideal for high-production environments, requiring less labor but more initial investment․ Manual machines are cost-effective for small businesses or limited production needs, providing precise control over filling amounts․ They are also easier to maintain and require less technical expertise compared to automated solutions․

15․2 When to Choose Manual Over Automatic

Manual bottle filling machines are ideal for small-scale production, startups, or businesses with limited budgets․ They are portable, easy to use, and require minimal training, making them perfect for small batches or unique bottling needs․ Manual machines are also preferred when precise control over filling amounts is crucial or when space and resources are limited․ Additionally, they are a cost-effective solution for businesses that do not require high-speed, automated operations․